Different Types of Turbochargers for Businesses

Jun 22,2022 | Brake

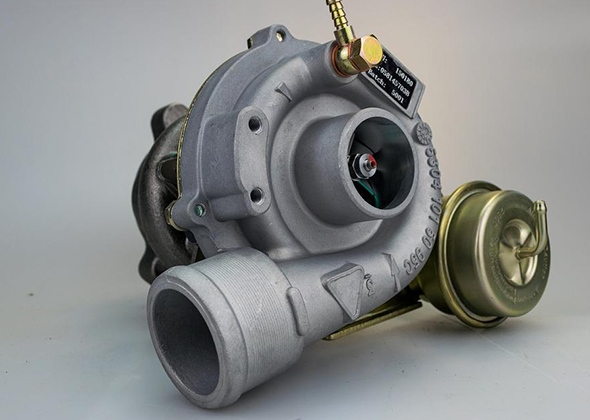

Turbochargers are centrifugal compressors driven by an exhaust gas turbine to boost the engine’s charge air pressure. Turbocharger performance affects all essential engine metrics, including fuel efficiency, power, and emissions. Before going into the mechanics of turbochargers, it’s critical to grasp a few basic ideas.

A turbocharger is a positive displacement compressor powered by the engine’s engine. It is a coaxial shaft system with two rotating shafts. The turbine shaft is connected to the exhaust gas turbine, which is placed within the exhaust channel of the engine and is powered by exhaust gas energy. The air compressor is connected to the compressor shaft through a shaft coupling. The compressor shaft is enclosed in its casing.

Read the full article because we will discuss the numerous types of turbochargers available.

What Is the Turbo Charger?

The turbocharger is the collective term for the turbocharger assembly as a whole. While this is accurate, it is misleading. The turbine and compressor are the rotating components of the turbocharger. The complete turbocharger assembly comprises three components: the spinning component, the turbine housing, and the compressor housing.

Because the turbine is propelled by exhaust gas, it is referred to as a centrifugal flow device. As the gas moves from the inner to the outside edges of the turbine wheel, its velocity increases. As a result, the exhaust gas velocity conditions in the turbine produce a wide variety of flow rates, allowing the turbocharger to operate at a high-efficiency level.

How Do They Work?

An air compressor, a turbine, and a controller comprise a turbocharger system. Compresses and delivers air to the turbocharger through the air compressor. The compressor is unique because its speed increases in lockstep with the input speed, comparable to a turbine.

Compressed air is sent from the compressor to the turbine, accelerating it before releasing it into the atmosphere. This high-speed air pressure drives the compressor. The compressor obtains energy (pressure energy) from the turbine due to a temperature differential (heating energy).

The controller is a computer-controlled device that manages the turbocharger’s operation. It controls the intake manifold’s air pressure and the compressor’s air pressure to manage the engine’s speed. The controller monitors the engine and has methods for shutting it down in the event of a turbocharger failure.

6 Types of Turbo Chargers

There are 6 different types of turbochargers that are commonly known within the automotive industry and are mentioned below:

- Single-Turbo

- Twin-Turbo

- Twin-Scroll Turbo

- Variable Geometry Turbo

- Variable Twin Scroll Turbo

- Electric Turbo

1. Single-Turbos

Single turbochargers are the turbochargers that most people believe exist, with their various component sizes and capacity to generate significantly different torque and characteristics.

Larger turbochargers nearly always provide greater top-end power, whereas smaller turbochargers can spool faster and generate more low-end power.

It was proven to be a cost-effective means of enhancing engine power It has since gained popularity, allowing smaller engines to increase their efficiency by producing the same amount of power as bigger naturally-aspirated engines while lighter.

These turbochargers are optimized for performance inside a specific RPM range, but drivers typically report suffering turbo lag until the turbo is enabled and the rev band hits its maximum.

Pros

- Compared to other techniques of enhancing the engine’s power and efficiency, this is a very cost-effective method.

- Easy to operate and often the most straightforward way of turbocharging, with a range of installation options.

- It enables smaller engines to generate the same power level as bigger normally aspirated engines, resulting in weight savings.

Cons

- Due to the limited effective RPM range of single turbos, sizing is complicated, as you must pick between appropriate low-end torque and greater high-end power.

- Turbo configurations may have a slower response time than non-turbo configurations.

2. Twin-Turbo

As the name implies, twin-turbos are engines equipped with a second turbocharger. Each bank of cylinders in a V6 or V8 engine is allocated a distinct turbocharger. A smaller turbo is employed at lower RPMs, but at higher RPMs, a much larger turbo is used.

Additionally, the twin sequential turbocharging technology offered a higher RPM range and increased performance with reduced turbo lag. This aids in the delivery of power at high RPMs. Additionally, the two turbos are used to enhance the complexity and associated costs of the system.

Pros

- Better performance with no weight penalty

- Extends the power band of the engine

- Reduces turbo lag

Cons

- More complex than a single turbo system

- Increased cost

3. Twin-Scroll Turbo

Twin-scroll turbochargers include a separated turbine housing and an exhaust manifold that individually couples the engine’s cylinders. For example, in a four-cylinder engine with a firing order of 1-3-4-2, cylinders 1 and 4 may feed a single turbo scroll, whereas cylinders 2 and 3 may feed a separate turbo scroll.

This design enables effective exhaust gas energy transfer to the turbo, resulting in extremely dense and pure air delivery to the cylinder. The amount of energy provided to the exhaust turbine determines the amount of power generated. There is a cost associated with these sorts of turbos since they address the complexity of a system that requires complex turbine housings, exhaust manifolds, and turbos.

Pros

- More durable than single-scroll turbos

- Provides for high-speed and low-speed power

- It is lighter than other turbos

Cons

- Extremely complex

- Harder to control exhaust back pressure

- Less space available

4. Variable Geometry Turbo

VGTs are turbochargers featuring an aerodynamic ring of vanes at the turbine inlet. Car and truck turbos can rotate synchronously to change gas swirl angle and cross-sectional area. Internal vanes adjust the turbo’s area-to-radius ratio to match the engine’s RPM.

Low RPM means low A/R ratio, which allows the turbo to spool up rapidly by increasing exhaust gas velocity. Higher rpm increases the A/R ratio, increasing airflow. A low boost threshold, reduced turbo delay, and a broad and smooth torque band.

While VGTs are widely utilized in diesel engines due to the cooling effect of exhaust gases, their application in gasoline engines has been limited due to high costs and the need for unusual materials. The vanes should be made of a heat-resistant material to avoid damage. This has been limited to premium automobiles and high-performance engines.

Pros

- The torque curve is relatively flat and broad. It is a powerful turbocharging technology that operates over a wide RPM range.

- It requires only one turbo, whereas a sequential turbo setup requires two.

Cons

- These are most frequently utilized in diesel applications due to the lower exhaust gases, which prevent the vanes from being destroyed by heat.

- Although gasoline applications are prohibitively expensive, they must be employed to preserve reliability. Although the technology was employed in the Porsche 997, only a few VGT gasoline engines are currently used due to their exorbitant cost.